As of August 2020, there are 565 operational LFG energy projects in the United States and 477 landfills that are good candidates for projects.

Landfill gas (LFG) is a natural byproduct of the decomposition of organic material in landfills. LFG is composed of roughly 50 percent methane (the primary component of natural gas), 50 percent carbon dioxide (CO2) and a small amount of non-methane organic compounds. Methane is a potent greenhouse gas 28 to 36 times more effective than CO2 at trapping heat in the atmosphere over a 100-year period, per the latest Intergovernmental Panel on Climate Change (IPCC) assessment report (AR5) Exit.

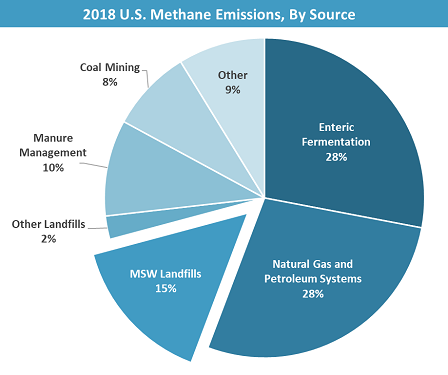

Note: All emission estimates from the Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2018.

Municipal solid waste (MSW) landfills are the third-largest source of human-related methane emissions in the United States, accounting for approximately 15.1 percent of these emissions in 2018. The methane emissions from MSW landfills in 2018 were approximately equivalent to the greenhouse gas (GHG) emissions from more than 20.6 million passenger vehicles driven for one year or the CO2 emissions from more than 11.0 million homes’ energy use for one year. At the same time, methane emissions from MSW landfills represent a lost opportunity to capture and use a significant energy resource.

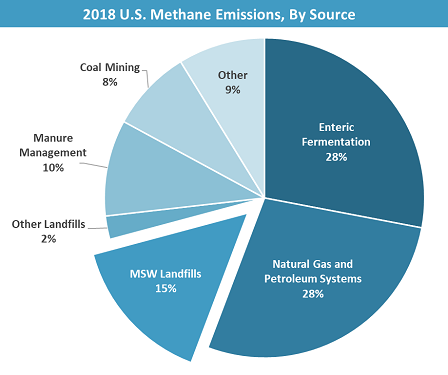

When MSW is first deposited in a landfill, it undergoes an aerobic (with oxygen) decomposition stage when little methane is generated. Then, typically within less than 1 year, anaerobic conditions are established and methane-producing bacteria begin to decompose the waste and generate methane.

The following diagram illustrates the changes in typical LFG composition after waste placement. Bacteria decompose landfill waste in four phases. Gas composition changes with each phase and waste in a landfill may be undergoing several phases of decomposition at once. The time after placement scale (total time and phase duration) varies with landfill conditions.

Figure adapted from ATSDR 2008. Chapter 2: Landfill Gas Basics. In Landfill Gas Primer - An Overview for Environmental Health Professionals. Figure 2-1, pp. 5-6. https://www.atsdr.cdc.gov/HAC/landfill/PDFs/Landfill_2001_ch2mod.pdf (PDF) (12 pp, 2MB) Exit

In October 2009, EPA issued a rule (40 CFR Part 98) that requires the reporting of (GHG) emissions from large sources and suppliers in the United States, and is intended to collect accurate and timely emissions data to inform future policy decisions.

Annually, EPA issues an inventory report to present the U.S. government's estimates of U.S. human-related GHG emissions and sinks for each year since 1990. Emissions from the waste sector as well as other sectors are presented in this inventory.

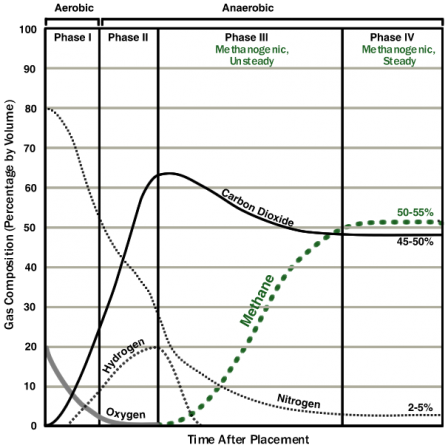

Instead of escaping into the air, LFG can be captured, converted, and used as a renewable energy resource. Using LFG helps to reduce odors and other hazards associated with LFG emissions, and prevents methane from migrating into the atmosphere and contributing to local smog and global climate change. In addition, LFG energy projects generate revenue and create jobs in the community and beyond. Learn more about the benefits of using LFG.

The graphic illustrates the collection and processing of LFG to produce methane for multiple uses. First, LFG is collected through vertical and horizontal piping buried in an MSW landfill. The LFG is then processed and treated for use. The graphic shows potential end uses of LFG including industrial/institutional uses, arts and crafts, pipeline gas, and vehicle fuel.

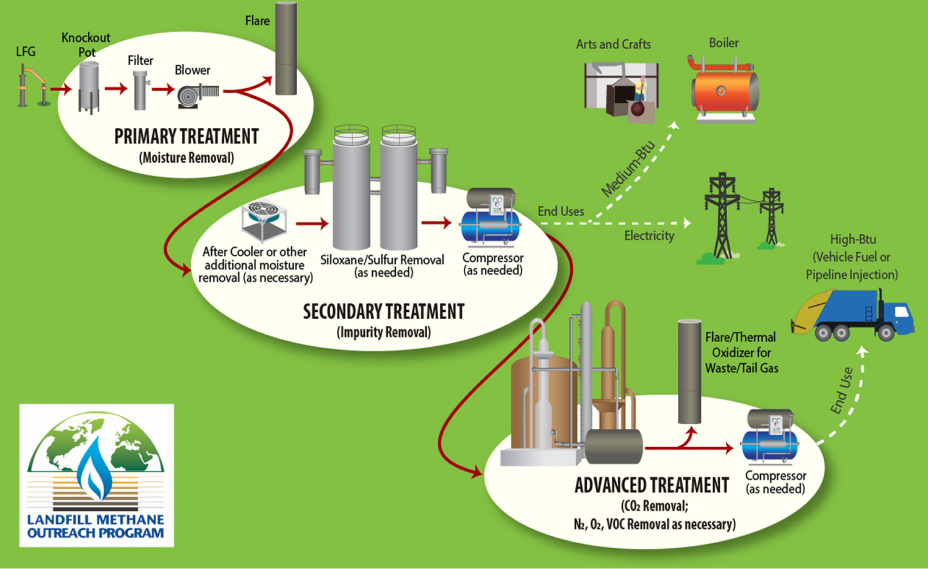

This graphic shows three stages of LFG treatment. Primary Treatment removes moisture as the gas passes through a knockout pot, filter, and blower. Secondary Treatment involves the use of an after cooler or other additional moisture removal (as necessary), followed by siloxane/sulfur removal and compression (as needed). After the impurities are removed in the Secondary Treatment stage, the LFG can be used to generate electricity or as a medium-Btu fuel for arts and crafts or boilers. Advanced Treatment removes additional impurities (CO2, N2, O2, and VOCs) and compresses the LFG into a high-Btu gas that can be used for vehicle fuel or injected into a gas pipeline. Waste/tail gas is sent to a flare or thermal oxidizer.

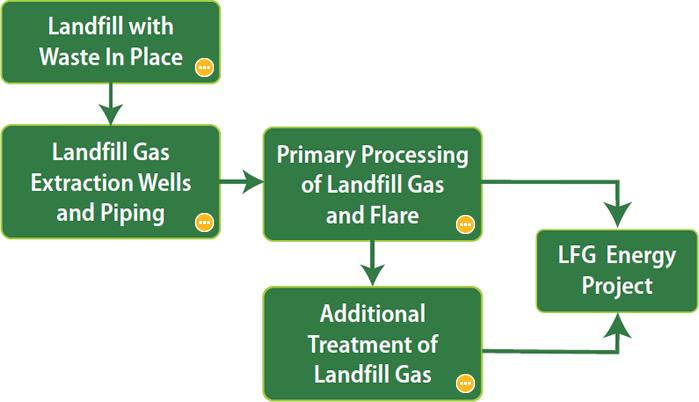

LFG is extracted from landfills using a series of wells and a blower/flare (or vacuum) system. This system directs the collected gas to a central point where it can be processed and treated depending upon the ultimate use for the gas. From this point, the gas can be flared or beneficially used in an LFG energy project. Click on the flowchart to view more details, including photographs of LFG collection and processing systems.

There are many options available for converting LFG into energy. Different types of LFG energy projects are grouped below into three broad categories – Electricity Generation, Direct Use of Medium-Btu Gas, and Renewable Natural Gas. Descriptions of project technologies are included under each project type. For more information on LFG energy project technology options and the advantages and disadvantages of each, see Chapter 3. Project Technology Options of LMOP’s LFG Energy Project Development Handbook.

About 71 percent of currently operational LFG energy projects in the United States generate electricity. A variety of technologies, including reciprocating internal combustion engines, turbines, microturbines and fuel cells, can be used to generate electricity for onsite use and/or sale to the grid. The reciprocating engine is the most commonly used conversion technology for LFG electricity applications because of its relatively low cost, high efficiency and size ranges that complement the gas output of many landfills. Gas turbines are typically used in larger LFG energy projects while microturbines are generally used for smaller LFG volumes and in niche applications.

Cogeneration, also known as combined heat and power (CHP), projects use LFG to generate both electricity and thermal energy, usually in the form of steam or hot water. Several cogeneration projects using engines or turbines have been installed at industrial, commercial and institutional operations, using engines or turbines. The efficiency gains of capturing the thermal energy in addition to electricity generation can make this project type very attractive.

Directly using LFG to offset the use of another fuel (for example, natural gas, coal or fuel oil) occurs in about 17 percent of the currently operational projects. LFG can be used directly in a boiler, dryer, kiln, greenhouse or other thermal application. In these projects, the gas is piped directly to a nearby customer for use in combustion equipment as a replacement or supplementary fuel. Only limited condensate removal and filtration treatment are required, although some modifications of existing combustion equipment might be necessary.

LFG can also be used directly to evaporate leachate. Leachate evaporation using LFG is a good option for landfills where leachate disposal at a water resource recovery facility is unavailable or expensive. LFG is used to evaporate leachate to a more concentrated and more easily discarded effluent volume.

Innovative direct uses of medium-Btu gas include firing pottery and glass-blowing kilns; powering and heating greenhouses; and evaporating waste paint. Current industries using LFG include auto manufacturing, chemical production, food and beverage processing, pharmaceuticals, cement and brick manufacturing, wastewater treatment, consumer electronics and products, paper and steel production, and prisons and hospitals.

LFG can be upgraded to renewable natural gas (RNG), a high-Btu gas, through treatment processes by increasing its methane content and, conversely, reducing its CO2, nitrogen and oxygen contents. RNG can be used in place of fossil natural gas, as pipeline-quality gas, compressed natural gas (CNG) or liquefied natural gas (LNG). About 12 percent of currently operating LFG energy projects are creating RNG.

Options for use of RNG include thermal applications, to generate electricity or as fuel for vehicles. The RNG can be used locally at the site where the gas is produced or can be injected into natural gas transmission or distribution pipelines for delivery to another location.

A municipal solid waste (MSW) landfill is a discrete area of land or excavation that receives household waste, and may also receive other types of nonhazardous wastes. Collection of LFG typically begins after a portion of a landfill, known as a “cell”, is closed to waste placement.

Compacting waste at an active landfill

Compacting waste at an active landfill  Waste trucks at active landfill

Waste trucks at active landfill  Closed cell of active landfill

Closed cell of active landfill  Closed landfill

Closed landfill

LFG collection systems can be configured as vertical wells or horizontal trenches. The most common method is drilling vertical wells into the waste mass and connecting the wellheads to lateral piping that transports the gas to a collection header using a blower or vacuum induction system. Horizontal trench systems are useful in areas of active filling. Some landfills use a combination of vertical wells and horizontal collectors. Collection system operators “tune” or adjust the wellfield to improve collection.

Drilling a vertical well

Drilling a vertical well

(Photo courtesy of Smith Gardner, Inc.)  Creating a trench to install a horizontal

Creating a trench to install a horizontal

collector  Lateral line from remote vertical wellhead

Lateral line from remote vertical wellhead

(Photo courtesy of Smith Gardner, Inc.)  Installing connection pipe to main header

Installing connection pipe to main header

(Photo courtesy of Smith Gardner, Inc.)  Wellhead and control valve

Wellhead and control valve

on vertical well  Group of vertical wellheads

Group of vertical wellheads

in portion of wellfield  Membrane over wellfield cover

Membrane over wellfield cover

(Photo courtesy of Smith Gardner, Inc.)  Performing pressure test on LFG pipe

Performing pressure test on LFG pipe

(Photo courtesy of Smith Gardner, Inc.)

A basic LFG processing skid includes a knock-out drum to remove moisture, blowers to provide a vacuum to “pull” the gas and pressure to convey the gas, and a flare. System operators monitor parameters to maximize system efficiency.

Basic processing skid with condensate removal (foreground), blowers and candlestick flare (background)

Basic processing skid with condensate removal (foreground), blowers and candlestick flare (background)  Basic processing skid with condensate removal, blowers and heat exchanger

Basic processing skid with condensate removal, blowers and heat exchanger  Enclosed LFG flare

Enclosed LFG flare

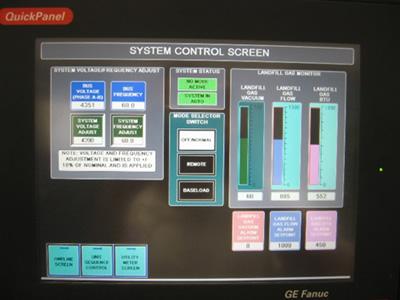

Skid-mounted control panels monitor LFG parameters such as vacuum, temperature and flowrate

Skid-mounted control panels monitor LFG parameters such as vacuum, temperature and flowrate  Interface output for LFG flow and gas quality (Photo courtesy of Smith Gardner, Inc)

Interface output for LFG flow and gas quality (Photo courtesy of Smith Gardner, Inc)  SCADA system to measure LFG flow to blower, flare and generator sets (Photo courtesy of Smith Gardner, Inc)

SCADA system to measure LFG flow to blower, flare and generator sets (Photo courtesy of Smith Gardner, Inc)

Using LFG in an energy recovery system usually requires some treatment of the gas to remove excess moisture, particulates and other impurities. The type and extent of treatment depend on site-specific LFG characteristics and the type of energy recovery system. Some end uses, such as pipeline injection or vehicle fuel projects, require additional cleaning and compression of the LFG.

Filters can remove chemical compounds such as siloxanes or hydrogen sulfide

Filters can remove chemical compounds such as siloxanes or hydrogen sulfide  Example of 600-horsepower compressor for an LFG pipeline injection project

Example of 600-horsepower compressor for an LFG pipeline injection project  Treatment towers at LFG pipeline injection project to remove CO2, water, hydrogen sulfide, siloxanes and other impurities through a physical solvent process

Treatment towers at LFG pipeline injection project to remove CO2, water, hydrogen sulfide, siloxanes and other impurities through a physical solvent process

Contact Us to ask a question, provide feedback, or report a problem.